3D Sand Printing ExOne

ExOne® 3D sand printers support sand casting applications in all sectors, allowing our customers to innovate and provide improved design options and solutions to their customers.

The future of industrial development continues to place high demands on foundries and suppliers. 3D sand printing is at the beginning of its potential.

As a leader in 3D sand printing additive manufacturing, ExOne offers solutions for complex and growing customer demands that cannot be met by any other production process. The incorporation of ExOne mold and sand core systems helps to improve operations and creates efficiency for industrial manufacturers who are advancing into the industry 4.0.

Our 3D sand printers can support prototyping, series production and parts on demand. Learn more about the versatility offered by 3D sand printers and how our systems can comply with the specialized requirements of your process.

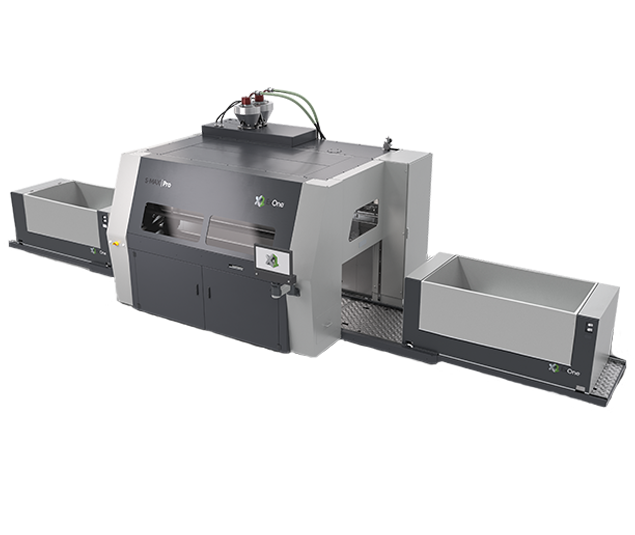

S-Max Pro

S-Max Pro ™ covers the entire range of 3D sand printing, from prototyping to mass production, and is capable of processing all ExOne alloy jet printing systems.

It is available as a standalone solution, but it is also scalable and can be connected by a network that creates a fully automated production line, to undertake industrial series production in 3D sand printing.

- Printable area 1.800 X 1.000 X 700 mm / 400H *

- Volume 1260 L

- Maximum production rate 100 – 135 * L / h (depending on the height of the layer 0,28 / 0,38 mm)

- Minimum layer height 0,26 – 0,38 mm

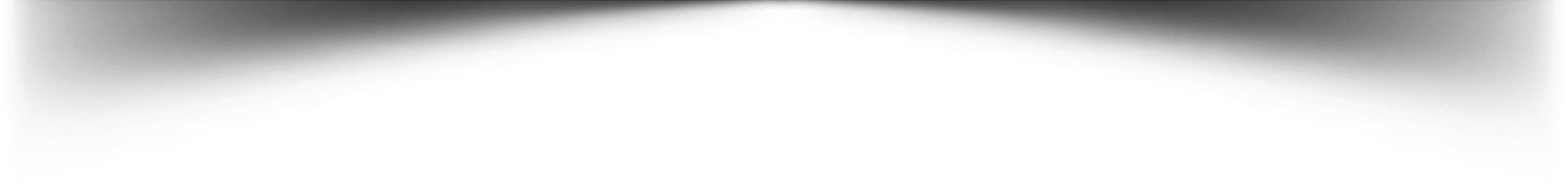

S-Print

Create complex sand cores and molds directly from 3D CAD data. The S-Print 3D sand core and mold system combines a compact structure with an extremely versatile range of applications.

With the flexibility to select any available alloy jet system from ExOne, S-Print sand molds can be manufactured to accommodate a variety of casting materials, for rapid product development and short-term production.

- Printable area 800 × 500 × 400 mm

- Volume 160 L

- Maximum production rate 36 L / h

- Minimum layer height 0,26 – 0,38 mm

S-Max

The S-Max 3D sand mold and core system is ideal for sand foundry companies, creates complex sand cores and molds directly from 3D CAD data, eliminating the need for a physical pattern to create a core or mold.

Casting capacity in hours without hard tools improves the entire casting process chain.

Get new efficiencies with our largest construction platform.

- Printable area 1.800 × 1.000 × 700 mm

- Volume 1260 L

- Maximum production rate 105 L / h

- Minimum layer height 0,26 – 0,38 m

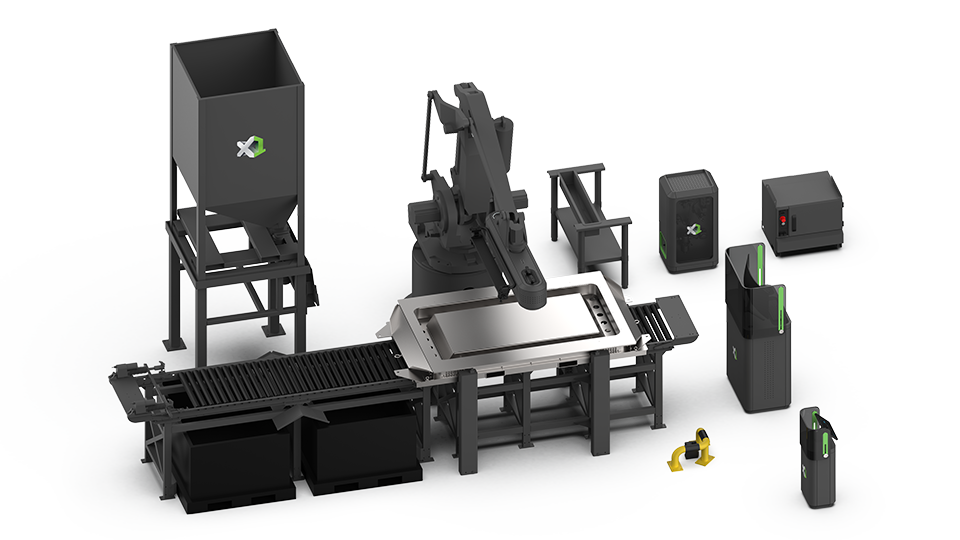

S-Max-Flex

The most affordable sand 3D printer ever offered by ExOne, S-Max Flex is designed to provide faster turnaround and easy integration into digital foundry operations.

Brand new additive robotic manufacturing system features an industrial robot with an end effector using Single Pass Blasting (SPJ) advanced for binder jetting in a telescopic work box.

- construction box 1.900 x 1.000 x 1.000 mm

- Built Volume 1.900 L

- Maximum construction rate of up to 115 l/h

- layer height 0,28 to 0,5 mm