3D Metal Printing Desktop Metal

Find the right metal 3D printer for your production needs, with dimensions, varied resources and production volume to support metal printing in all sectors and applications.

Over 20 years of experience in 3D metal printing, we are constantly innovating and developing this knowledge platform to boost the sector.

Our metal 3D printers are capable of handling complex geometries, fine powders and a wide variety of types of materials, all with precision, limited downtime and a friendly interface.

Explore model specifications or contact us for a quote to learn more.

Production system

P1

Designed to bridge the gap between benchtop development and mass production, the P-1 offers the same excellent part quality as the P-50 with greater process flexibility.

Featuring a state-of-the-art printbar with 1200 active dpi, an inert processing environment and Desktop Metal's patent-pending Single Pass Jetting technology, the P-1 handles non-reactive and reactive materials at speeds in excess of 10 times those of laser powder bed fusion technologies⁴ and is capable of printing multiple builds per shift and direct process transfers to the P-50.

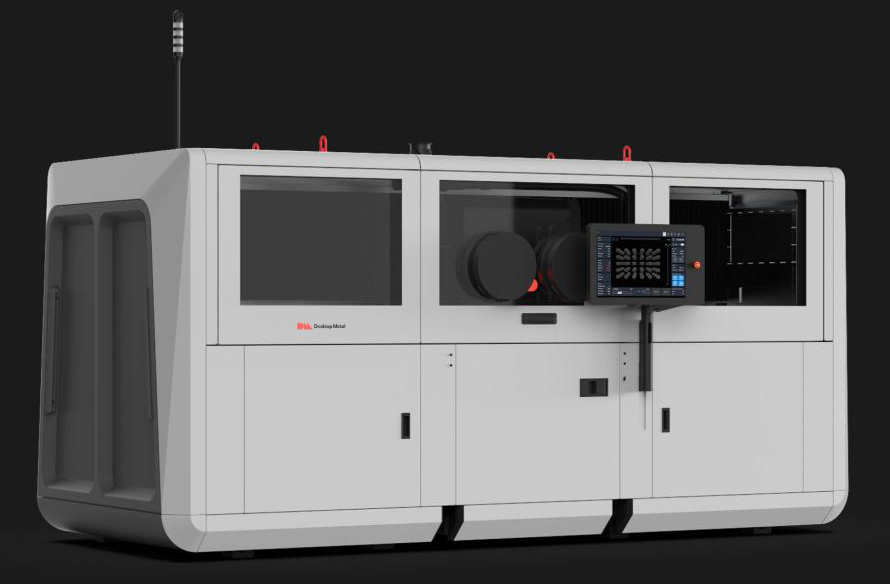

P50

Designed to be the fastest way to 3D print metal parts at scale, the P-50 leverages Desktop Metal's Single Pass Jetting technology, patent pending, and bidirectional printing to achieve speeds up to 100 times greater than powder bed laser fusion technologies⁴, producing parts in volumes and costs competitive with conventional mass production techniques.

Featuring a state-of-the-art printbar with 1200 active dpi, an inert processing environment and constant wave scattering for printbed uniformity, the P-50 offers the quality, reliability and economy needed for high volume, end customer applications.

Series X

InnoventX

The most compact binder jet 3D printer for the production of metal parts, ceramic or composite.

Launched in 2018, this easy-to-use system features Triple ACT and a piezoelectric printhead.

It is suitable for education, search, prototyping, rapid product development and short-term production of small components.

X25PRO

This advanced mid-volume BINDER jet 3D printing system is already being used globally for the production of metal parts., ceramics and composites.

Launched in 2020, this system features Triple ACT and a piezoelectric print head.

It is suitable for research, prototyping, rapid product development, short run production or continuous production 24 hours per day, 7 days a week.

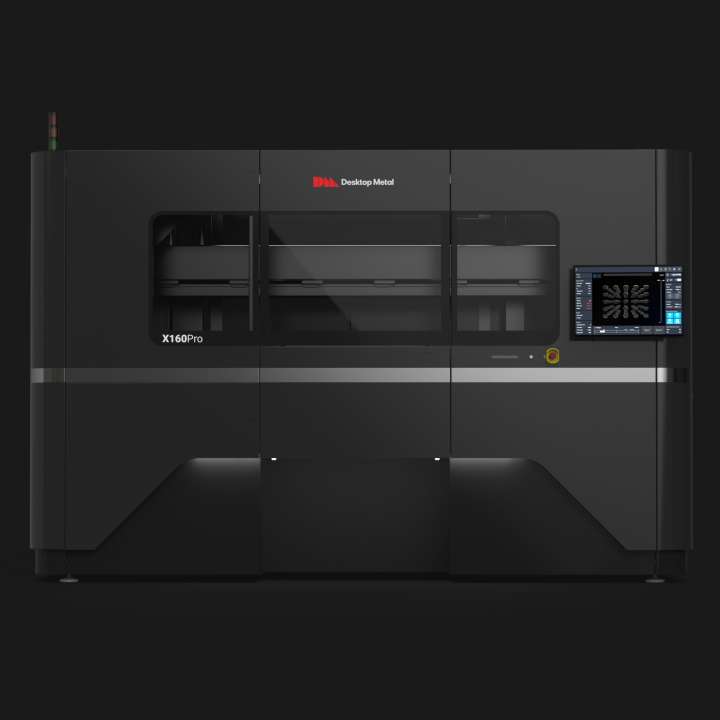

X160PRO

The world's largest BINDER jet 3D printer for the production of metal parts, ceramic or composite.

This system features Triple ACT and a piezoelectric printhead..

It was designed for continuous production 24 hours per day, 7 days a week, but supports short run production, rapid product development and even research and prototyping.

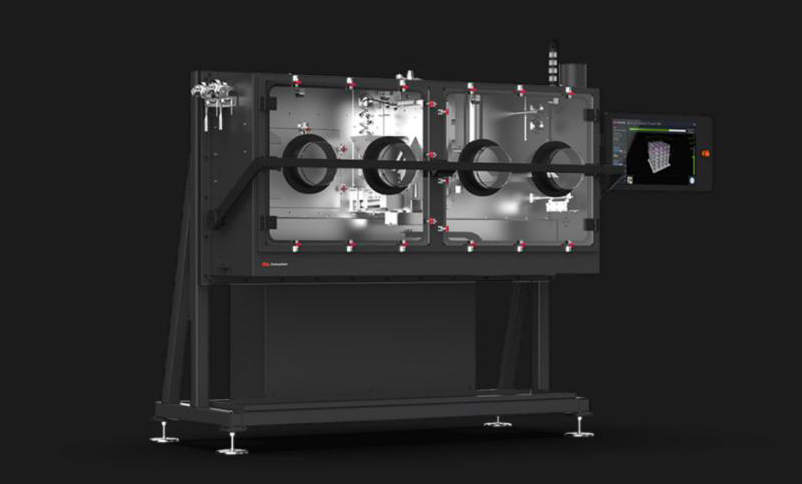

Shop System

The world's first metal binder blasting system designed to bring 3D metal printing to machine shops.

In addition to the standard out-of-the-box system, Desktop Metal also offers Shop System™+ and Shop System™ Pro packages for added flexibility, functionality and value.

Shop System Forust Edition is also available for wood.

The system is composed of:

3D Printing

The Shop System™ printer features the most advanced printhead on the market, over 70.000 beaks gushing drops of 1,2 pL a quase 10 kHZ for high-resolution 3D printed parts at a fraction of the cost of laser-based systems.¹

Stove

after printing, the construction box containing the printed parts is placed in a crosslinking furnace.

Crosslinking is a thermal curing process that imparts additional strength to printed parts in the green state prior to dust removal..

Metallic Dust Removal Station

With easy access portholes, a manual air collector, integrated dust screening and recycling, and a vacuum port for easy dust maintenance, powder station provides closed-loop powder management and recycling.

Sintering Furnace

The Shop System™ Furnace is a shop-safe high temperature sintering furnace, Built for economical high throughput of 3D printed parts.

Featuring external gas connection and adjustable shelves, oven can be easily and economically sized for medium manufacturing volumes.

Studio System 2

Office-friendly metal 3D printing in just 2 stages — Print. Sinter, now available.

3D Printing

Unlike laser-based systems that selectively melt metal powder, Studio System extrudes bound metal rods – similar to how an FDM printer works.

This eliminates many of the security requirements usually associated with metal 3D printing., while enabling new features, such as the use of fully closed cell padding for lightweight strength.

Sintering Furnace

Designed to be the easiest to use sinter furnace, the Studio System oven 2 first heat the parts to remove all binders from the parts and, then, raises temperature to near-melt to deliver industrial-strength sintering in an office-friendly package.

Built-in temperature profiles tuned for each construction and material ensure uniform heating and cooling without the residual stresses introduced in laser-based systems.