TEM (Thermal Deburring)

(Thermal Deburring)

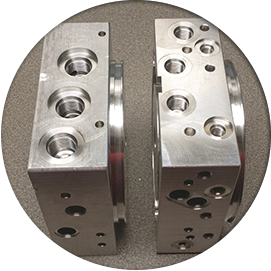

Compliance with quality standards for finished surfaces in complex components can be a challenge for the manufacturing industry, especially when the production time is a critical factor.

The finishing process offered by EXTRUDE HONE ®, achieves complete grinding and removing injection leaks of a highly efficient manner.

The process uses the combustion of methane gas inside a pressurized Chamber to remove burrs as encrustations or hidden contaminants of machined components through an oxidation reaction.

How the TEM process works:

- The ratio between fuel and oxygen and pressurization level is determined based on heat transfer rate of the material of the component, burr or fouling thickness and size of the lot.

- A spark ignition system creates the heat required to ignite the compressed gases. This results in a heat wave reaching 6,000° F for only a few milliseconds.

- Due to the fact of burrs or encrustations are much smaller than the component, they reach the autoignition point your instantly and are oxidized in oxygen-rich camera long before the component can be harmed.

- The mass of the component acts as a heat sink during the oxidation process.

- The gases surrounding all burrs and carvings, allowing your complete removal, regardless of the location of the component. This results in a component free of any loose particles.

- Burrs removed form an oxide powder that is redistributed across the surface of the component as a dry film loosely connected that is not chemically bound.

- Each component the deburring or removed the waste is kept loose in a basket for special purposes (non-critical parts) or set on a plate and, then, placed inside the combustion chamber for processing.