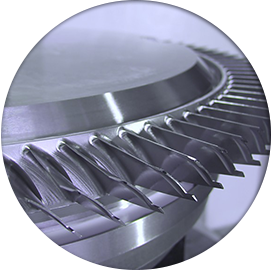

PECM (Precise Electrochemical Machining)

(Usinagem Eletroquímica Precisa)

It can be difficult to find the best surface machining process for their production operations when their machining tolerances are very demanding. We offer a solution that can fit into many of these manufacturing applications, our precision Electrochemical Machining process (PECM).

The PECM process works under the same principles of our ECM machines with the difference that a higher precision can be achieved.

In SHORT, PECM OFFERS ALL THE ADVANTAGES OF OUR ECM PROCESS – ACCURACY, QUALITY, CONSISTENCY AND REPEATABILITY-WITH THE ADVANTAGE OF GREATER PRECISION FOR SPECIALIZED APPLICATIONS.

Our PECM unit is composed of four sets; Mechanics, Aqua, Control and strength. These sets make the PECM unit get high precision results for finished components.

As the PECM process works:

- PECM boosts the cathode on the workpiece, keeping a little distance (until 10 µm) throughout the complete cycle time.

- The oscillating movement is needed to ensure passage and washing with the electrolyte.

- CC pulse occurs only in the shortest distance.

- The quality of the cathode and the conditions of distance are tracked to ensure the desired results.

- Both modes of oscillation and non-oscillation are available to ensure increased productivity.

- Bipolar CC pulse is incorporated in the process that cleans the cathode during and after machining cycle to maintain constant operating conditions.

- A totally controlled process, that includes a quality control system

- The operator interface provides a clear representation of the process steps that reduces the complexity of the operation.

- Standardized power generators, tank control of electrolyte and the relevant parameters of electrolytes regulated work together to precisely control the conditions of distance

- An ergonomic operation inside a locked workspace that includes an automatic entry for the protection of workers, along with a ventilated work area are used to maximize operator safety.